ANALOG RESISTIVE

From standard touch panel technology to the latest advancements in ergonomic functionality and usability, GUNZE touch panels and controllers provide unparalleled accuracy and durability in even the most demanding environments.

We have developed a wide array of panels and films to meet the most demanding needs of our customers—from low reflective film to extremely durable Tough Touch panels, all of our products are designed to match the exacting requirements and highest standards of our users.

The future of touch panel technology is very exciting and GUNZE is ready for the challenge. We are constantly developing new and improved ways to enhance the user experience in all our products. Whether for industrial, warehousing, military, medical, retail or other applications, our mission is to make complex operations simple by enhancing efficient interaction between people and technology. We constantly strive for great customer experiences with both our products and our company.

GUNZE low reflective touch panels provide a solution for direct lighting. Reduce reflectivity and improve visibility with GUNZE’s patented technology

GUNZE low reflective touch panels provide a solution for direct lighting. Reduce reflectivity and improve visibility with GUNZE’s patented technology

An ideal choice for applications operating in direct sunlight and where power consumption is critical:

BENEFITS OF GUNZE LOW REFLECTIVE TOUCH PANELS

- Enhanced visibility even in direct sunlight

- Patented polarization technology reduces reflection and improves visibility

- Anti-reflective films available for greater transparency and reduced reflectivity

- 4H-9H films available for added durability

Low Reflectivity

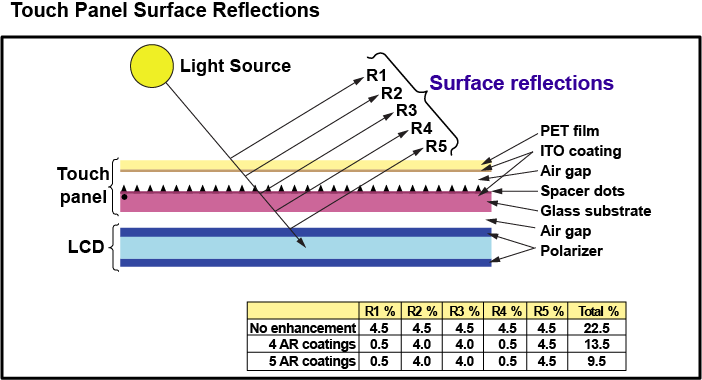

Light reflection is one of the major factors that can considerably lessen the visibility of LCDs. As a pioneer in the touch panel industry, GUNZE has developed a proprietary Indium Tin Oxide (ITO) low-reflective layer that improves touch panel transparency. The ITO layer allows light to pass through the horizontal surfaces with little or no reflection.

Reflection Reduction Methods

GUNZE low-reflective touch panels employ anti-reflection film and polarization to minimize reflection.

Anti-Reflection Film

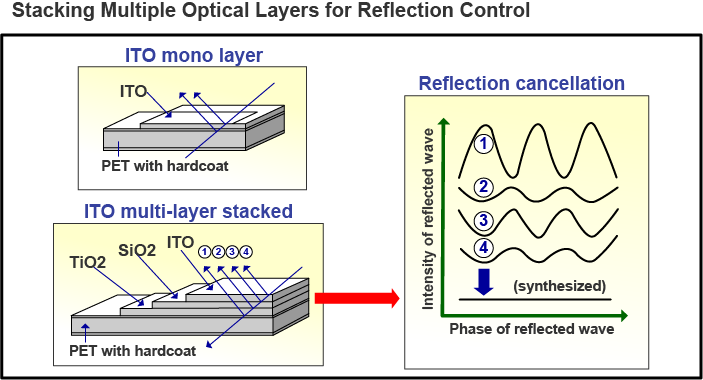

Surface light reflection is lowered by a layer of anti-reflective (AR) film composed of multiple transparent materials, each of which has a different light reflection rate. The film coherently adds an amplitude of light reflection at the film boundaries, reducing touch panel light reflection by as much as 10%. AR film reduces reflection by controlling the amplitude and phase of light waves.

Note: Coherency is a condition in which the wave phases of light waves synchronize with each other.

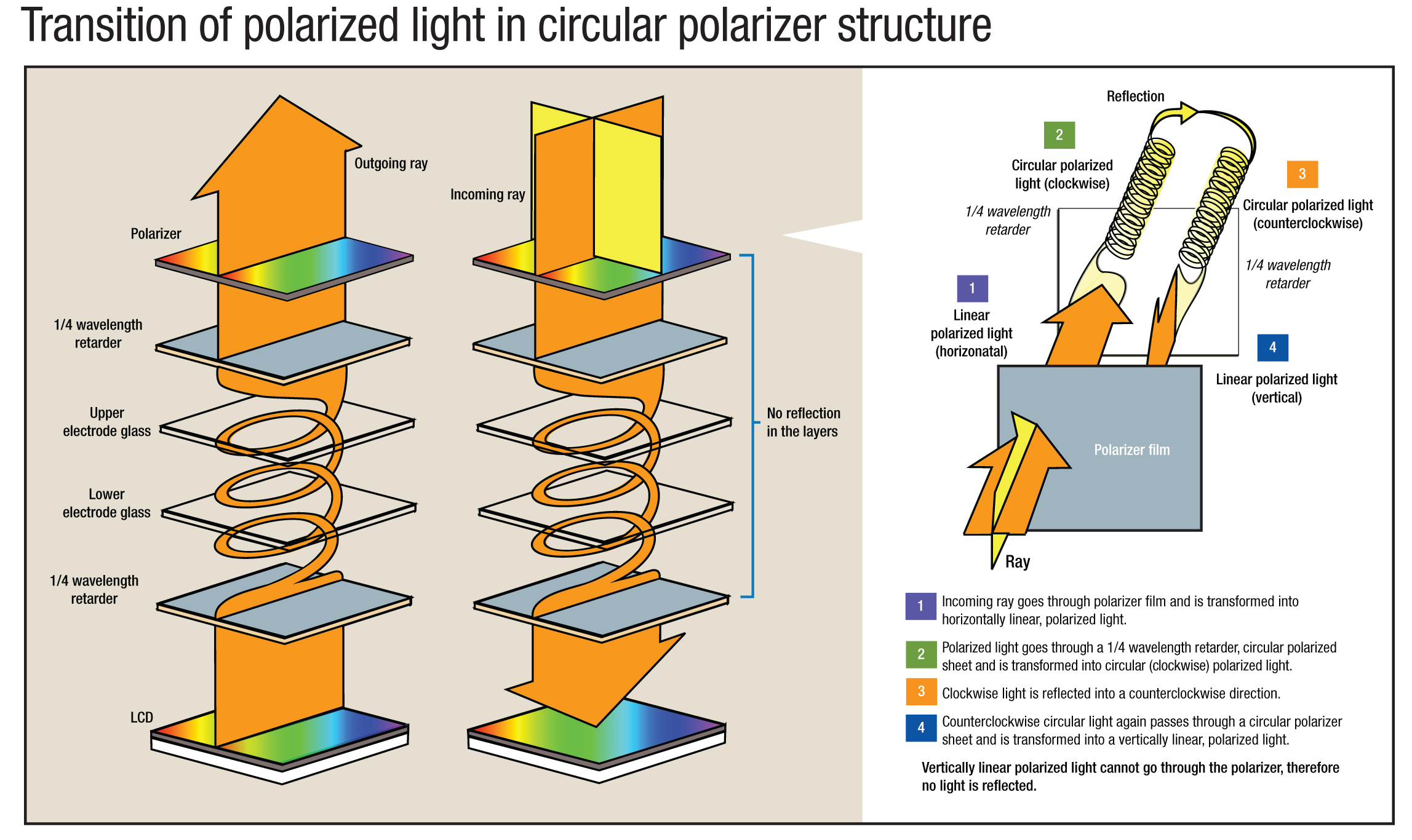

Polarization

In addition to AR film, GUNZE touch panels utilize polarization, which reduces reflection even more. A polarizer is a type of light isolator that reduces reflective light from inside the touch panel.

Note: An optical isolator is a component of a light element circuit that has a pair of input/output terminals. It is a passive optical component that passes light only in a designated direction, letting light in with minimal loss while greatly reducing output light.

Materials such as glass that are optically equiangular and therefore have no complicative light refraction are covered with the polarizer, which replaces the standard polytelephthalate (PET) layer. GUNZE’s innovative resin-based light refracting material offers superior reflection reduction.

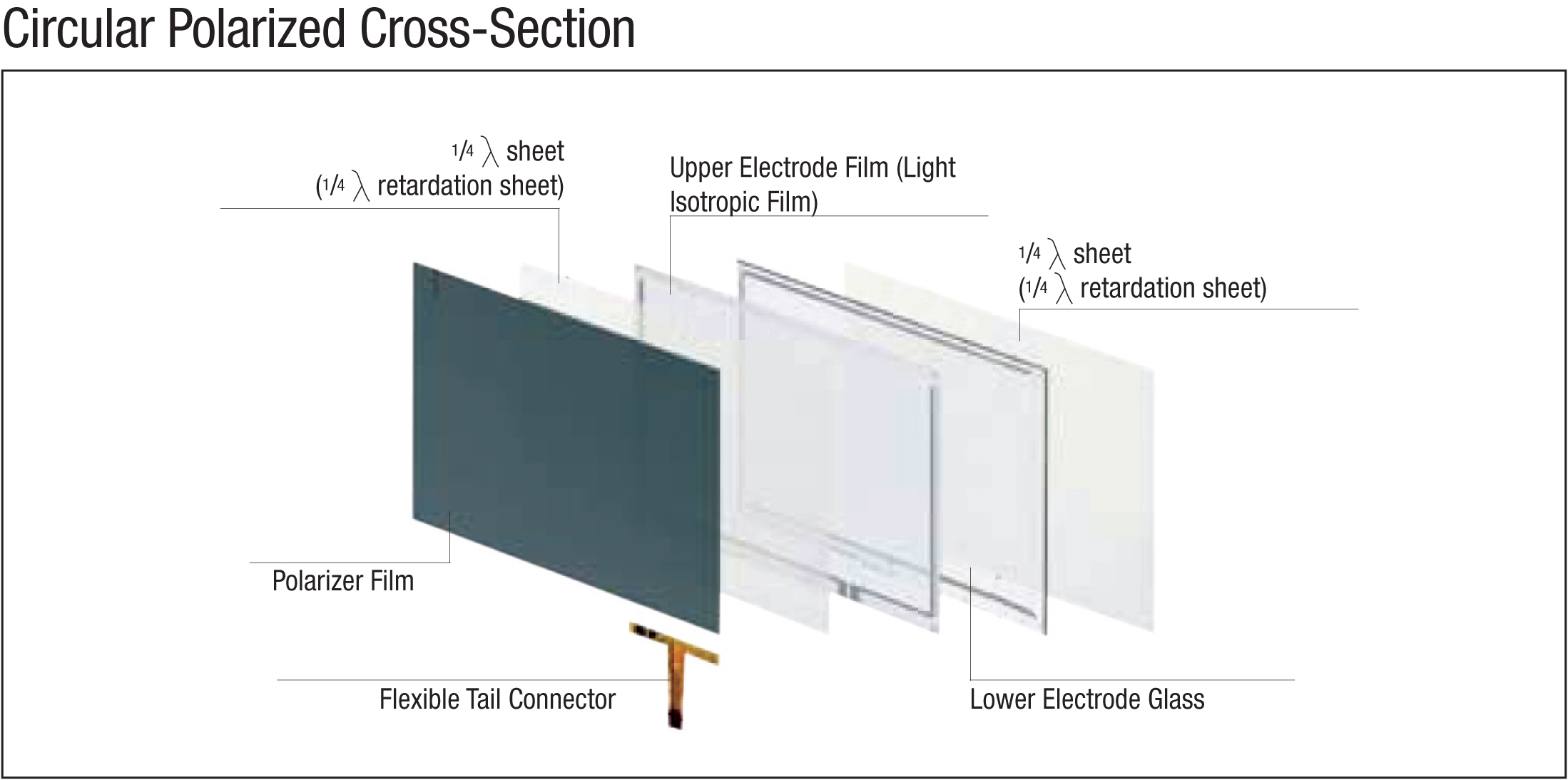

Circular Type Polarizer

The circular polarizer converts certain linear light waves (such as 550 nm) to circular light. A linear polarizer and 1/4 retardation sheet form an adhesive layer. Linear light and circular light can be combined in a clockwise or counterclockwise direction, crossing each other squarely, with one type of crossing being transparent while the other is not.

Light from inside the touch panel is absorbed by the circular polarizer. Because the transparency of light absorbed by the polarizer is reduced, the circular polarizing sheet attached to the surface of the LCD has a 1/4 retardation rate, enabling the required transparency.

Layered Anti-Reflective Film

Anti-reflection (AR) treatment to the surface of the touch panel is a highly effective means of reducing light reflection.

A single layer of AR film affects only a narrow range of visible light waves; multiple layers of AR film prevent light reflection in a broad range of light waves.

GUNZE’s AR technology now makes it possible to manufacture touch panels with low reflection that are also highly durable and that can utilize both pen and finger input.

GUNZE’s AR technology prevents light reflection on the surface, with a high transparency rate. With standard touch panels, the AR coating is placed on the upper electrode film. With low reflective touch panels, the AR coating is on the polarizer.

Multiple anti-reflective films that increase transmissivity and reduce reflectivity.

Multiple anti-reflective films that increase transmissivity and reduce reflectivity.

An ideal choice for applications operating in various lighting conditions, or where power conservation is required:

Mobile Computing

Mobile Computing- Medical Equipment

- Military Equipment

- Aerospace Equipment

Benefits of anti-reflective touch panels

Highly transmissive, incorporating

Highly transmissive, incorporating

anti-reflective technology- Overlay choices from 2H-9H

- Clear color contrast indoors and outdoors

- Multiple glass options available

Layered Anti-reflective Film

Adding anti-reflection (AR) treatment to the surface of the touch panel is a highly effective means of reducing light reflection.

A single layer of AR film effects only a narrow range of visible light waves; multiple layers of AR film prevent light reflection in a broad range of light waves. GUNZE’s AR technology now makes it possible to manufacture touch panels with low reflection that are also highly durable and that can utilize both pen and finger input. GUNZE’s AR technology prevents light reflection on the surface, with a high transparency rate. With high-transmissive touch panels, the AR coating can be placed on multiple layers of the touch panel stack-up.

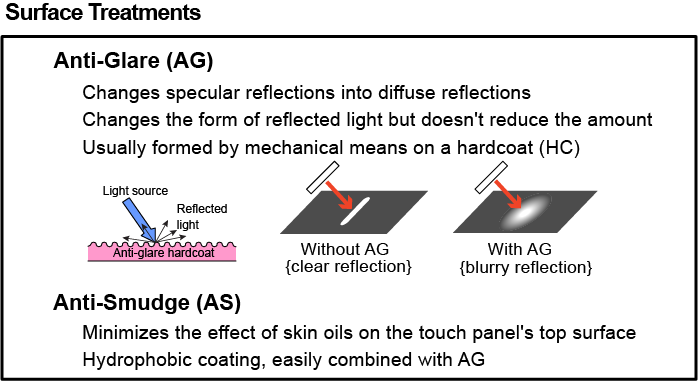

Additional Surface Treatment Options

GUNZE offers optional surface treatments that further enhance the performance and durability of the touch panel. GUNZE’s anti-glare film changes specular reflections into diffused reflections. It changes the form of reflected light, but does not reduce the amount of reflected light. When added to the touch panel stack, anti-glare film helps to minimize glare from ambient light on the touch panel surface.

GUNZE’s anti-smudge film minimizes the effect of skin oils on the touch panel surface by using a hydrophobic coating combined with an anti-glare coating. This helps to mask smudges that the end-user may find undesirable.

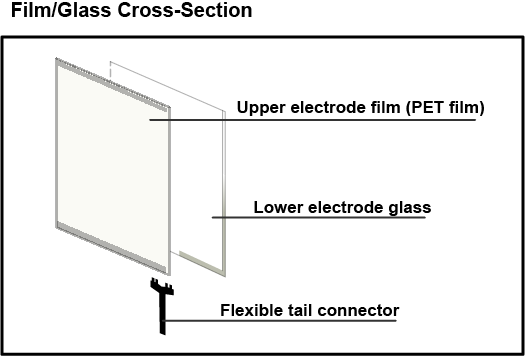

Film/Glass touch panels are the most commonly used transparent touch panel

Film/Glass touch panels are the most commonly used transparent touch panel

Film/Glass touch panels are used in countless devices and products. They are the foundation for every analog resistive touch product we manufacture, and are available in 4-, 5-, and 8-wire configurations. GUNZE touch panels are of the highest quality, with GUNZE’s reputation for quality, and years of touch panel manufacturing experience, built into every one. Our Film/Glass touch panels are a cost-effective way to integrate GUNZE quality into your product. GUNZE Film/Glass touch panels offer excellent optical quality. We incorporate an anti-glare coating on the top film to minimize light reflected from the touch panel surface. We also have options for anti-fingerprint film, anti-reflective film and different levels of anti-glare.

GUNZE Film/Glass touch panels are available in a large number of standard touch panel designs. Odds are that we already have available a standard offering that can be incorporated into your designs. Offering a large selection of standard products enables GUNZE to help provide you with options that help you minimize your project start-up costs. GUNZE can also design custom Film/Glass touch panels for your specific application. Please contact GUNZE for assistance in finding the Film/Glass touch panel that’s right for you.

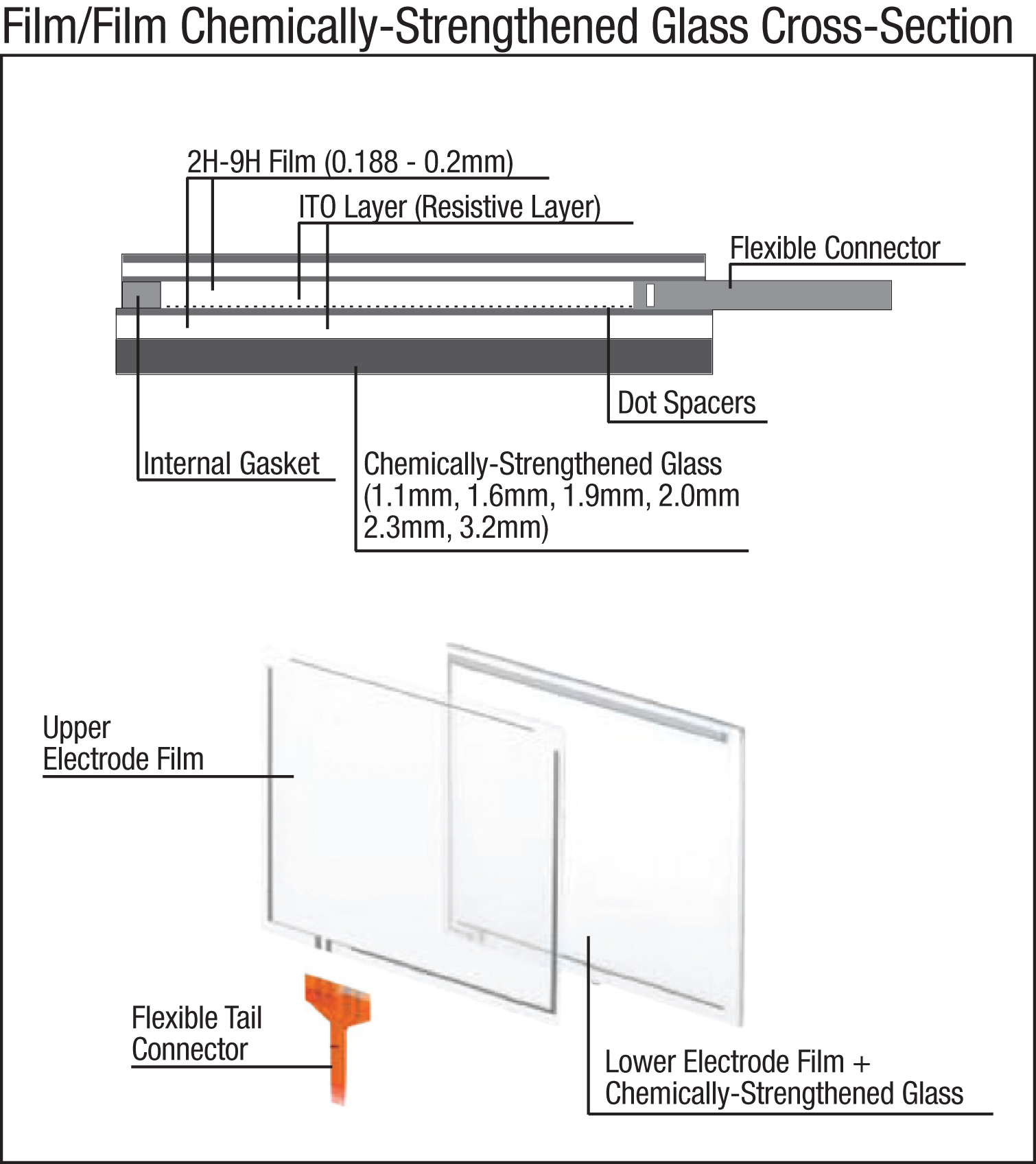

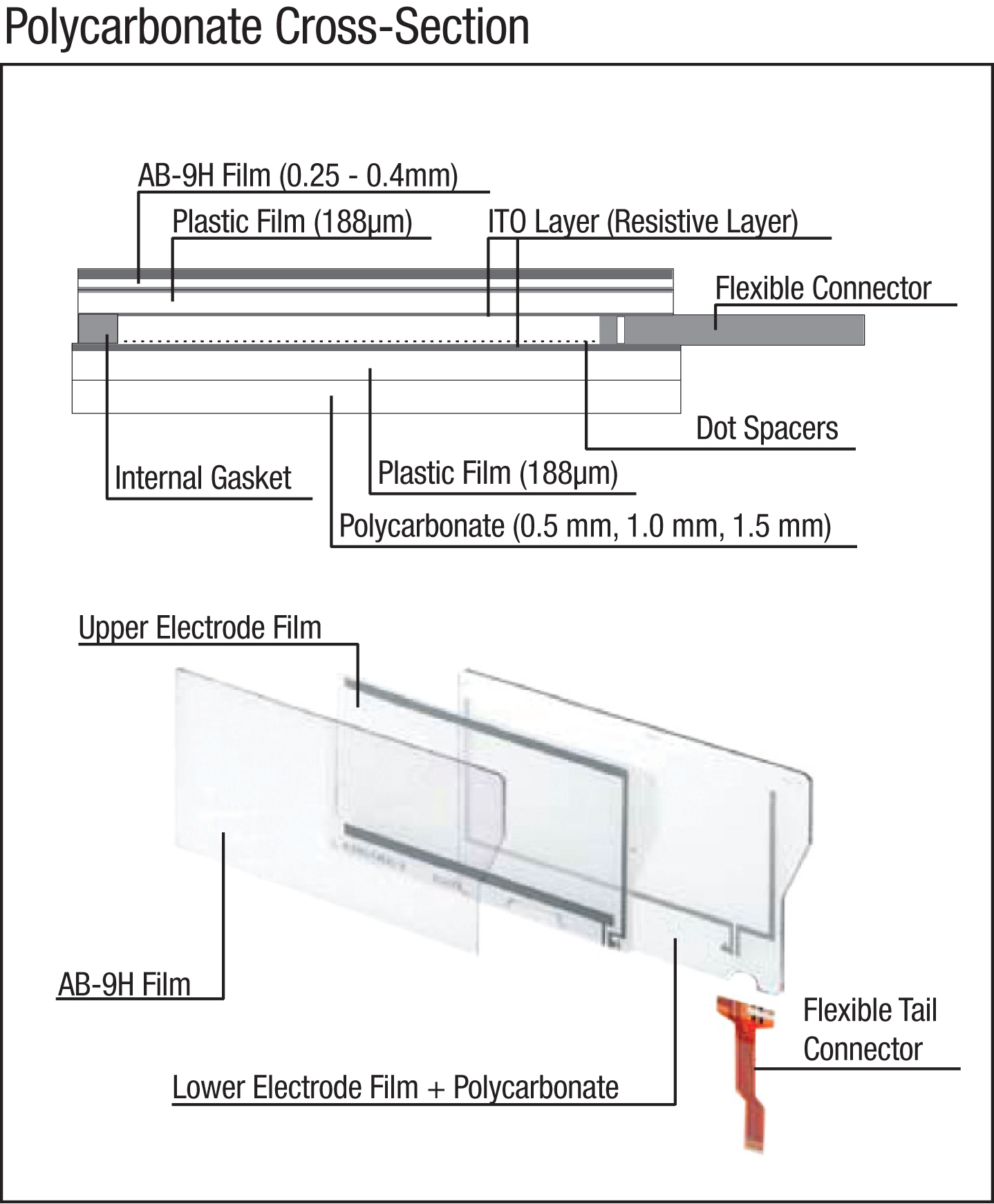

Tough touch panels use polycarbonate or chemically-strengthened glass to assure durability, yet are lightweight, compact.

Tough touch panels use polycarbonate or chemically-strengthened glass to assure durability, yet are lightweight, compact.

Durable materials create a vast array of durable designs An ideal choice for applications operating in harsh environments or where durability is important:

Benefits of GUNZE Tough Touch Panels

- Highly durable

- Overlay choices from 2H-9H

- Polycarbonate substrates offer lightweight durability

- Chemically strengthened glass substrates increase impact resistance

Lightweight Yet Durable Plastic Construction

Answering the demand for lightweight, plastic materials suitable for use in PDAs, Gunze combines a Film-Film (F-F) touch panel with a plastic substrate. The electrodes are comprised of 0.1-0.2mm thick ITO coated film. These are adhered to a 1-2mm thick plastic substrate.

Answering the demand for lightweight, plastic materials suitable for use in PDAs, Gunze combines a Film-Film (F-F) touch panel with a plastic substrate. The electrodes are comprised of 0.1-0.2mm thick ITO coated film. These are adhered to a 1-2mm thick plastic substrate.

Polycarbonate Touch Panels

GUNZE adjusts the heat expansion coefficients of the polycarbonate material used in its touch panels, overcoming warping problems that can result when plastic is used instead of glass.

In addition to being lightweight and fracture resistant, polycarbonate can be shaped in any way imaginable, enabling design possibilities other than traditional rectangles or squares. Note: Maximum 6.4 diagonal

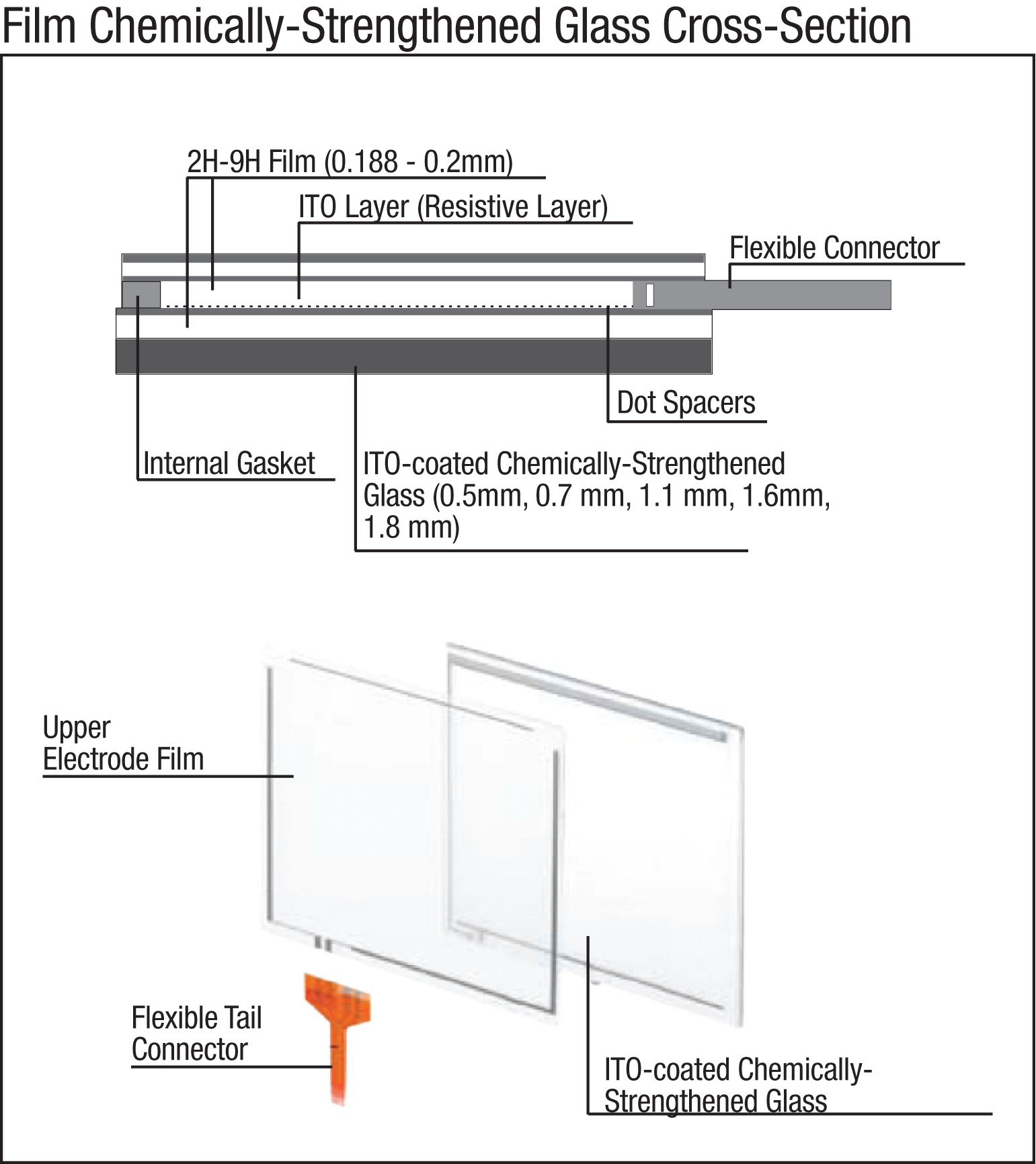

Chemically-Strengthened Glass Touch Panels

GUNZE creates rugged touch panels by substituting the standard glass in Film-Glass panels with chemically strengthened glass. Chemically strengthened glass is twice as durable and impact resistant than standard glass.